Formulating Cosmetics: Evaporation

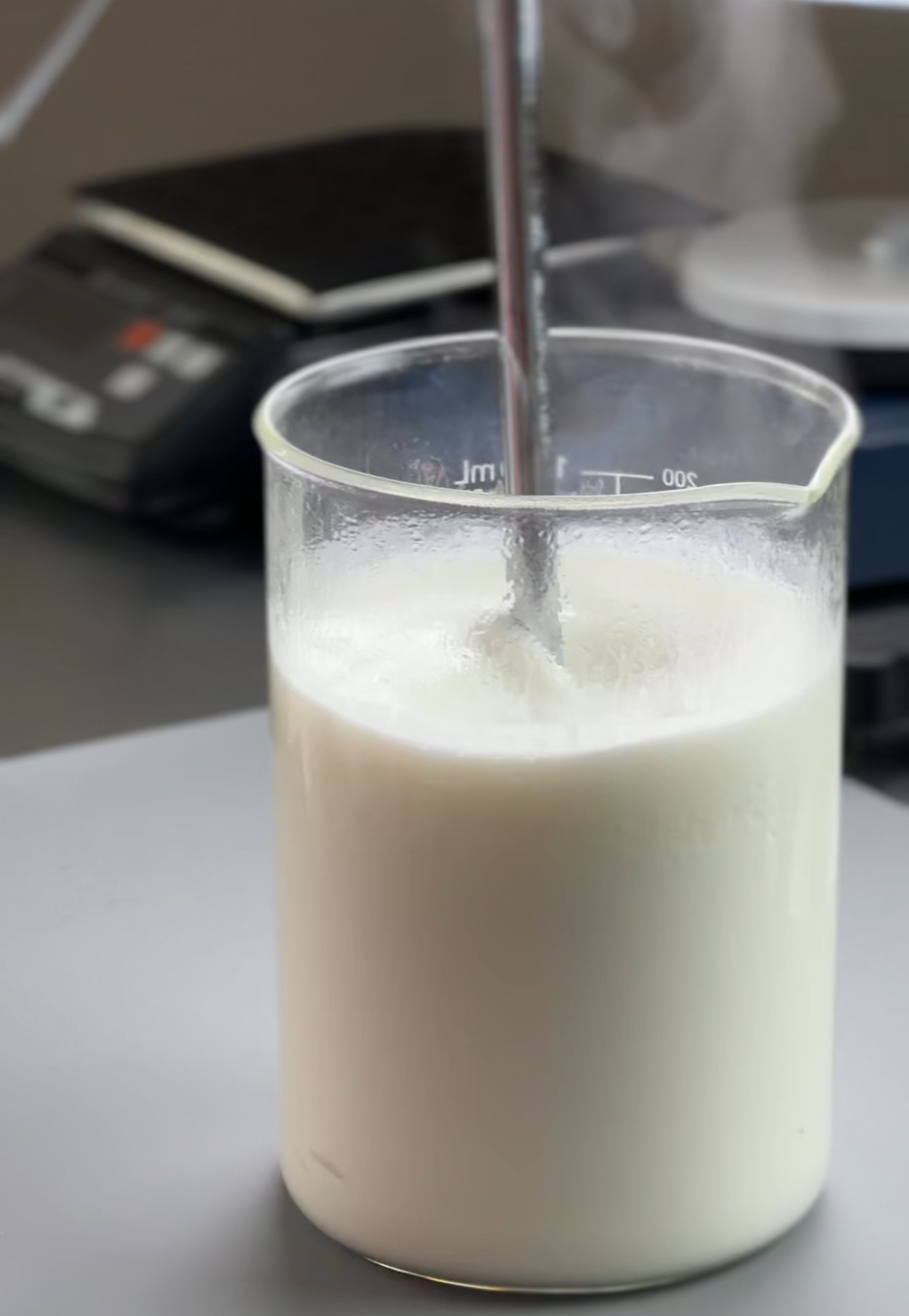

Evaporation is when matter changes to a vapor. This needs to be taken into consideration when heating water. Evaporation affects the viscosity of lotions, creams, moisturizer, and conditioners. If too much water is evaporated, the viscosity of the formulation may be too thick. Some factors affecting the evaporation are the batch size, the amount of water and time it takes to heat the water, the time it takes for the formulation to cool, and the type of vessel being used.

2 Techniques to Determine Water Loss

1. Record the weight of the vessel before adding any ingredients to it. After heating the ingredients to temperature, weigh the vessel again and subtract the weight to determine water loss. Add the lost water amount back into formulation.

2. A general rule of thumb is the evaporation will be approximately 10%. Calculate 10% of the formula and add that amount of water into the formulation.

Evaporation also occurs with volatile materials like essential oils. If essential oils are added to a hot formulation, the essential oils will burn off, evaporate, losing valuable scent and therapeutic properties. Try adding essential oils below 110°F/43°C. Some formulations such as a thick cream may become too thick to pour into a container at this temperature and you may have to add the essential oils while the lotion is still thin enough to pour. It depends on the container you are using and the system you are using to fill the container such as hand fill compared to a bottle-filling machine.

Learn More

This information can be found in the Lesson: Formulating Cosmetics: Making the Formulation in the Pro Formulation Courses. The Pro Courses teach in depth how to formulate including GMP, Testing, Preservatives, Labeling, Ingredients, Resources and tried and tested formulations.

You might also like